1. Uhlalutyo lwesakhiwo

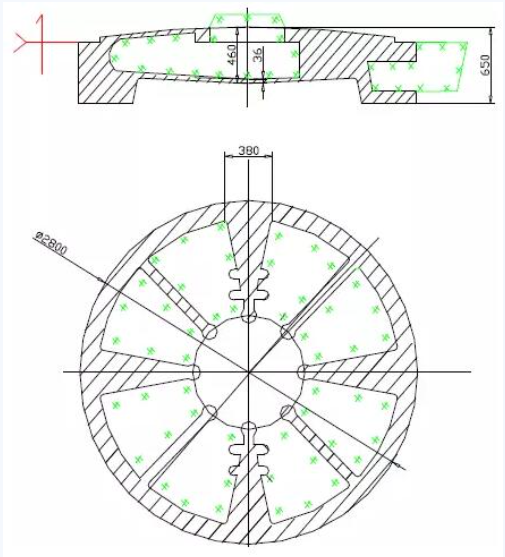

(1) Okuivalvu yebhabhathaneinesakhiwo esijikelezileyo esimile okwekhekhe, umngxuma wangaphakathi uqhagamshelwe kwaye uxhaswe ziimbambo ezi-8 zokuqinisa, umngxuma ophezulu we-Φ620 unxibelelana nomngxuma wangaphakathi, kunye nezinye izinto eziseleyoivalvuivaliwe, isiseko sesanti kunzima ukusilungisa kwaye kulula ukusenza siguquguquke. Ukukhupha umoya kunye nokucocwa komngxuma wangaphakathi kuzisa ubunzima obukhulu, njengoko kubonisiwe kuMfanekiso 1.

Ubukhulu bodonga lwee-castings buyahluka kakhulu, ubukhulu bodonga bufikelela kwi-380mm, kwaye ubukhulu bodonga buncinci yi-36mm kuphela. Xa i-cast iqina, umahluko wobushushu mkhulu, kwaye ukuncipha okungalinganiyo kunokuvelisa ngokulula imingxuma yokuncipha kunye neziphene ze-shrinkage porosity, eziya kubangela ukuvuza kwamanzi kuvavanyo lwe-hydraulic.

2. Uyilo lwenkqubo:

(1) Umphezulu wokwahlulwa uboniswe kuMfanekiso 1. Beka isiphelo esinemingxunya kwibhokisi ephezulu, yenza umbindi wesanti opheleleyo kumngxuma ophakathi, kwaye wolule intloko engundoqo ngokufanelekileyo ukuze kube lula ukubambelela kombindi wesanti kunye nokuhamba kombindi wesanti xa ibhokisi ijikeleziswa. Izinzile, ubude bentloko engundoqo yecantilever yemingxunya emibini engaboniyo ecaleni bude kunobude bomngxuma, ukuze iziko lobunzima bombindi wesanti lonke lithambekele ecaleni kwentloko engundoqo ukuqinisekisa ukuba umbindi wesanti uzinzile kwaye uzinzile.

Inkqubo yokugalela evaliweyo kancinci iyasetyenziswa, ∑F ngaphakathi: ∑F ethe tye: ∑F ethe tye=1:1.5:1.3, i-sprue isebenzisa ityhubhu yeseramikhi enobubanzi obungaphakathi be-Φ120, kwaye iziqwenga ezibini zezitena ezichaseneyo ze-200×100×40mm zibekwe ezantsi ukuthintela isinyithi esinyibilikisiweyo ukuba singangeni ngqo. Kwisikhunta sesanti esichaphazelekileyo, kufakwe isihluzo seseramikhi se-foam se-150×150×40 ezantsi kwerunner, kwaye iityhubhu zeseramikhi ezili-12 ezinobubanzi obungaphakathi be-Φ30 zisetyenziselwa irunner yangaphakathi ukuba iqhagamshelane ngokulinganayo ezantsi kwe-casting ngetanki yokuqokelela amanzi ezantsi kwerunner ukwenza isicwangciso sokugalela esisezantsi, njengoko kubonisiwe kuMfanekiso 2. I-Essence

(3) Beka imingxunya yomoya eyi-14 ∮20 kwisikhunta esingaphezulu, beka umngxuma womoya wesanti oyintloko ye-Φ200 embindini wentloko eyintloko, beka intsimbi ebandayo kwiindawo ezinkulu neziqinileyo ukuqinisekisa ukuqina okulinganayo kwe-casting, kwaye usebenzise umgaqo wokwandisa i-graphitization ukurhoxisa. I-feeding riser isetyenziselwa ukuphucula isivuno senkqubo. Ubungakanani bebhokisi yesanti yi-3600×3600×1000/600mm, kwaye idityaniswe ngepleyiti yentsimbi enobukhulu be-25mm ukuqinisekisa amandla aneleyo kunye nokuqina, njengoko kubonisiwe kuMfanekiso 3.

3. Ulawulo lwenkqubo

(1) Ukumodela: Ngaphambi kokuba umodele, sebenzisa isampulu eqhelekileyo ye-Φ50×50mm ukuvavanya amandla okucinezelwa kwesanti yeresin ≥ 3.5MPa, kwaye uqinise intsimbi ebandayo kunye nerunner ukuqinisekisa ukuba isikhunta sesanti sinamandla aneleyo okuthintela igrafiti eveliswayo xa intsimbi enyibilikisiweyo iqinisa ukwanda kweekhemikhali, kwaye uthintele intsimbi enyibilikisiweyo ukuba ingachaphazeli inxalenye yerunner ixesha elide ukuze ibangele ukuhlanjwa kwesanti.

Ukwenziwa kwesiseko: Isiseko sesanti sahlulwe saba ziinxalenye ezisi-8 ezilinganayo ngeembambo ezisi-8 zokuqinisa, ezidityaniswe ngomngxuma ophakathi. Akukho zinye iindawo zenkxaso kunye nezokukhupha ngaphandle kwentloko ephakathi. Ukuba isiseko sesanti asinakulungiswa kwaye i-Exhaust, ukufuduka kwesiseko sesanti kunye nemingxunya yomoya kuya kuvela emva kokuthululwa. Ngenxa yokuba indawo iyonke yesiseko sesanti inkulu, yahlulwe yaba ziinxalenye ezisibhozo. Kufuneka ibe namandla aneleyo kunye nokuqina ukuqinisekisa ukuba isiseko sesanti asiyi konakala emva kokukhululwa kwesikhunta, kwaye asiyi konakala emva kokuthululwa. Ukuguquka kwenzeka, ukuze kuqinisekiswe ubukhulu bodonga obufanayo be-casting. Ngenxa yesi sizathu, senze ngokukodwa ithambo elikhethekileyo lesiseko, saza salibopha kwithambo eliphambili ngentambo yokungenisa umoya ukuze sitsale igesi yokukhupha umoya kwintloko eyintloko ukuqinisekisa ukuba isikhunta sesanti sixinene xa senziwa isiseko. Njengoko kubonisiwe kuMfanekiso 4.

(4) Ibhokisi yokuvala: Xa ucinga ukuba kunzima ukucoca isanti engaphakathi kwivalvu yebhabhathane, lonke undoqo wesanti upeyintwe ngeeleya ezimbini zepeyinti, undoqo wokuqala upeyintwe ngepeyinti ye-zirconium esekelwe kwi-alcohol (iBaume degree 45-55), kwaye undoqo wokuqala upeyintwe kwaye utshiswe. Emva kokomiswa, peyinta undoqo wesibini ngepeyinti ye-magnesium esekelwe kwi-alcohol (iBaume degree 35-45) ukuthintela ukuba ukuphoswa kunganamatheli kwisanti nokusila, okungenakucocwa. Inxalenye yentloko engundoqo ixhonywe kumbhobho wentsimbi we-Φ200 wesakhiwo esiphambili sethambo elingundoqo ngee-screw ezintathu ze-M25, eziqinisiweyo kwaye zitshixiwe ngebhokisi yesanti yesikhunta ephezulu enezikrufu kwaye zijongwe ukuba ubukhulu bodonga lwenxalenye nganye buyafana na.

4. Inkqubo yokunyibilikisa nokuthulula

(1) Sebenzisa intsimbi yehagu ye-Q14/16# ekumgangatho ophezulu ye-Benxi ephantsi kwe-P, S, Ti, kwaye uyifake kwi-ratio ye-40% ~ 60%; izinto ezincinci ezifana ne-P, S, Ti, Cr, Pb, njl. zilawulwa ngokungqongqo kwi-scrap steel, kwaye akukho mhlwa kunye neoyile ezivunyelweyo, i-addition ratio yi-25% ~ 40%; i-charge ebuyiselweyo kufuneka icocwe ngokudutyulwa kwee-shot phambi kokuba isetyenziswe ukuqinisekisa ukucoceka kwe-charge.

(2) Ulawulo oluphambili lwenxalenye emva kwesithando somlilo: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (intsalela): 0.035% ~0.05%, phantsi kwengcamango yokuqinisekisa i-spheroidization, umda ophantsi we-Mg (intsalela) kufuneka uthathwe kangangoko.

(3) Unyango lokugonyela i-spheroidization: kusetyenziswa ii-spheroidizers ezine-magnesium ephantsi kunye nezinqabileyo zomhlaba ezingaphantsi, kwaye umlinganiselo wokongeza yi-1.0% ~ 1.2%. Unyango lwe-spheroidization oluqhelekileyo lwendlela yokufunxa, i-0.15% yokugonyela kube kanye igqunywe kwi-nodulizer ezantsi kwephakheji, kwaye i-spheroidization igqityiwe. I-slag emva koko ikhutshelwa ngaphantsi ukuze igonyelwe okwesibini kwe-0.35%, kwaye igonyelwe ukuhamba kwe-0.15% yenziwa ngexesha lokugalela.

(5) Inkqubo yokuthulula ngokukhawuleza kubushushu obuphantsi iyasetyenziswa, ubushushu bokuthulula yi-1320°C~1340°C, kwaye ixesha lokuthulula yi-70~80s. Isinyithi esinyibilikisiweyo asinakuphazanyiswa ngexesha lokuthulula, kwaye indebe ye-sprue isoloko igcwele ukuthintela igesi kunye nezinto eziqukiweyo ukuba zingabandakanyeki kwi-mold ngokusebenzisa umngxuma.

5. Iziphumo zovavanyo lokufaka i-cast

(1) Vavanya amandla okutsalwa kwebhloko yovavanyo lwe-cast: 485MPa, ukunwebeka: 15%, ubunzima beBrinell HB187.

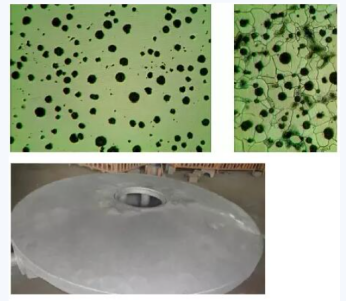

(2) Izinga le-spheroidization yi-95%, ubungakanani be-graphite yi-grade 6, kwaye i-pearlite yi-35%. Isakhiwo se-metallographic siboniswe kuMfanekiso 5.

(3) Akukho ziphene zirekhodiweyo ezifunyenweyo ekufumaneni iziphene zesibini ze-UT kunye ne-MT kwiindawo ezibalulekileyo.

(4) Inkangeleko ithe tyaba kwaye igudile (jonga uMfanekiso 6), ngaphandle kokwenza iziphene ezifana nokufakwa kwesanti, ukufakwa kweslag, ukuvalwa okubandayo, njl.njl., ubukhulu bodonga buyafana, kwaye ubukhulu buhlangabezana neemfuno zemizobo.

(6) Uvavanyo loxinzelelo lwe-hydraulic lwe-20kg/cm2 emva kokucubungula aluzange lubonise nakuphi na ukuvuza

6. Isiphelo

Ngokweempawu zesakhiwo sale valve yebhabhathane, ingxaki yokuguquguquka okungazinziyo nokulula kwesiseko sesanti esikhulu esiphakathi kunye nokucoca isanti okunzima kusonjululwa ngokugxininisa kuyilo lwesicwangciso senkqubo, ukuveliswa kunye nokulungiswa kwesiseko sesanti kunye nokusetyenziswa kweengubo ezisekelwe kwi-zirconium. Ukubekwa kwemingxuma yomoya kuthintela ukubakho kweembobo kwi-castings. Ukusuka kwinkqubo yokulawula itshaja yesithando kunye ne-runner, isikrini sesihluzo se-ceramic se-foam kunye netekhnoloji ye-ceramic ingate ziyasetyenziswa ukuqinisekisa ubunyulu besinyithi esinyibilikisiweyo. Emva konyango oluninzi lwe-inculation, ulwakhiwo lwe-metallographic lwe-castings kunye nokusebenza okubanzi kuye kwafikelela kwiimfuno ezisemgangathweni zabathengi.

UkususelaTianjin Tanggu Water-seal valve Co., Ltd. Ivalvu yebhabhathane, ivalvu yesango, Isihluzo se-Y, ivalvu yokujonga ipleyiti ezimbini ye-waferimveliso.

Ixesha lokuthumela: Epreli-29-2023