Ivalvu yokulinganisela engashukumiyo ye-TWS Flanged

Inkcazo:

Ivalvu yokulinganisela ye-TWS Flanged Static yimveliso ebalulekileyo yebhalansi ye-hydraulic esetyenziselwa ukulawulwa ngokuchanekileyo kokuhamba kwamanzi kwinkqubo yemibhobho yamanzi kwisicelo se-HVAC ukuqinisekisa ibhalansi ye-hydraulic engashukumiyo kwinkqubo yonke yamanzi. Olu luhlu lunokuqinisekisa ukuhamba kokwenyani kwesixhobo ngasinye sesiphelo kunye nombhobho ngokuhambelana nokuhamba koyilo kwinqanaba lokuqala lenkqubo ngokusebenza kwindawo kunye nekhompyutha yokulinganisa ukuhamba. Olu luhlu lusetyenziswa kakhulu kwimibhobho ephambili, imibhobho yamasebe kunye nemibhobho yesixhobo sesiphelo kwinkqubo yamanzi ye-HVAC. Ingasetyenziswa nakwezinye iinkqubo ezineemfuno ezifanayo zomsebenzi.

Iimbonakalo

Uyilo lwepayipi olulula kunye nokubala

Ufakelo olukhawulezayo nolulula

Kulula ukulinganisa nokulawula izinga lokuhamba kwamanzi kwindawo ngekhompyutha yokulinganisa

Kulula ukulinganisa uxinzelelo lomahluko kwindawo

Ukulinganisela phakathi kokunciphisa istroke ngokuseta kwangaphambili kwedijithali kunye nomboniso wokuseta kwangaphambili obonakalayo

Ixhotyiswe ngee-cocks zovavanyo loxinzelelo zombini ukuze kulinganiswe uxinzelelo olwahlukileyo. Ivili lesandla elinganyukiyo ukuze kube lula ukusebenza.

Isikrufu sokuthintela ukubetheka sikhuselwe ngesiciko sokukhusela.

Isiqu sevalvu esenziwe ngentsimbi engagqwaliyo i-SS416

Umzimba wesinyithi ophoswe ngopende olumelana nokugqwala lwe-epoxy powder

Izicelo:

Inkqubo yamanzi ye-HVAC

Ufakelo

1. Funda le miyalelo ngononophelo. Ukungayilandeli kungonakalisa imveliso okanye kubangele imeko eyingozi.

2.Jonga amanqaku anikwe kwimiyalelo nakwimveliso ukuqinisekisa ukuba imveliso ifanelekile kwisicelo sakho.

3. Umfaki kufuneka abe ngumntu oqeqeshiweyo nonamava okunika inkonzo.

4. Soloko uhlawula ngokucokisekileyo xa ugqibile ukufaka.

5. Ukuze imveliso ingasebenzi kakuhle, indlela efanelekileyo yokufaka kufuneka iquke ukuhlanjwa kwenkqubo, unyango lwamanzi ngamachiza kunye nokusetyenziswa kwesihluzo sendlela esecaleni se-50 micron (okanye esincinci). Susa zonke izihluzo ngaphambi kokuba uhlanjwe. 6. Cebisa ukusebenzisa umbhobho oqhelekileyo ukwenza ukuhlanjwa kwenkqubo kokuqala. Emva koko faka ivalvu kwipayipi.

6. Musa ukusebenzisa izongezo zebhoyila, i-solder flux kunye nezinto ezimanzisiweyo ezisekelwe kwi-petroleum okanye ezineoyile yeminerali, iihydrocarbons, okanye i-ethylene glycol acetate. Iikhompawundi ezinokusetyenziswa, kunye ne-50% yamanzi axutyiweyo, yi-diethylene glycol, i-ethylene glycol, kunye ne-propylene glycol (izisombululo ze-antifreeze).

7. Ivalvu ingafakelwa kwicala elifana nelotolo emzimbeni wevalvu. Ukufakelwa gwenxa kuya kukhokelela ekukhubazekeni kwenkqubo ye-hydronic.

8.Ii-packing case ezimbini eziqhotyoshelweyo. Qinisekisa ukuba kufuneka zifakwe ngaphambi kokuba ziqaliswe kwaye zihlanjwe. Qinisekisa ukuba azonakalanga emva kokufakwa.

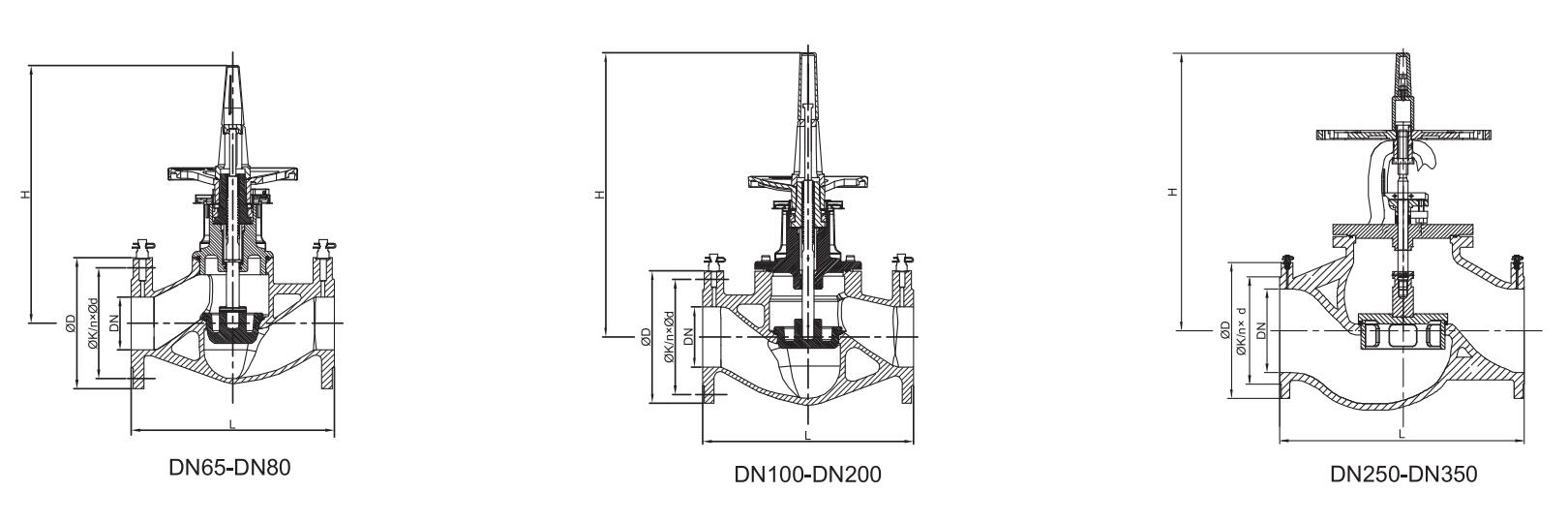

Ubukhulu:

| DN | L | H | D | K | n*d |

| 65 | 290 | 364 | 185 | 145 | 4*19 |

| 80 | 310 | 394 | 200 | 160 | 8*19 |

| 100 | 350 | 472 | 220 | 180 | 8*19 |

| 125 | 400 | 510 | 250 | 210 | 8*19 |

| 150 | 480 | 546 | 285 | 240 | 8*23 |

| 200 | 600 | 676 | 340 | 295 | 12*23 |

| 250 | 730 | 830 | 405 | 355 | 12*28 |

| 300 | 850 | 930 | 460 | 410 | 12*28 |

| 350 | 980 | 934 | 520 | 470 | 16*28 |